Model X Launch: Tesla Factory Shuts Down To Install More KUKA Robots To Speed Up Production

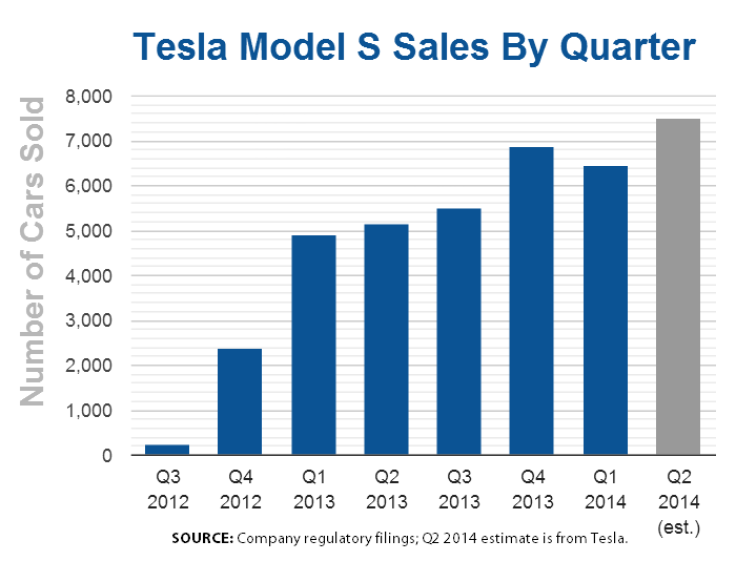

Since the release of its Model S electric luxury sedan in late 2012, Tesla Motors has been grappling with a good problem, but a problem nonetheless.

While orders keep pouring in for the first mass-produced battery electric vehicle (BEV) to top 200 miles in range, the company can’t fill them fast enough from its sole Fremont, California, factory.

If you order a Model S today in the U.S., don’t expect delivery until the fall. Orders from Europe and China are taking longer as the company juggles fulfilling U.S. orders while maintaining a steady stream of shipments to overseas markets, namely Northern Europe and China.

Tesla Motors Inc. (NASDAQ:TSLA) spokesman Simon Sproule told Bloomberg that his company has halted production for two weeks to install more robotics and other equipment to speed up production of the Model S and to prepare for the release next spring of the Model X crossover SUV. The company’s current production pace is just under 800 cars a week.

“It gets us ready to build X and to do it on the same line as the S,” Sproule told Bloomberg by phone. Financial details and the effect of the production stoppage will be addressed in more detail when Tesla releases its second-quarter financial results on July 31.

Most of the company’s 370-acre Fremont facility is currently unused, and this marks the first significant expansion at the plant since the company bought it from New United Motor Manufacturing, Inc., a joint venture between Toyota Motor Corp. (TYO:7203) and General Motors Co. (NYSE:GM), for $42 million in 2010. In its prime during the '60s and '70s, the Fremont facility churned out over 1,000 Chevrolets, Pontiacs and Oldsmobiles a day for GM.

But those days of blue-collar manual assembly of American gas guzzlers are gone. Tesla has turned a portion of the site into one of the more advanced manufacturing facilities. The company will be installing more so-called flexible robotics manufactured by Augsburg, Germany, plant engineering firm KUKA AG (ETR:KU2), which sells its multi-joint robotics arms to Daimler AG (ETR:DAI), Bayerische Motoren Werke AG (ETR:BMW) and other major auto manufacturers. Unlike the stamp-and-repeat robots of yore, modern flexible robotic assembly machines can perform different and increasingly intricate tasks.

To demonstrate the capabilities of the more advanced robotic arms, KUKA released this video in March showing one of its robots defeating table tennis champion Timo Boll at his own game.

© Copyright IBTimes 2024. All rights reserved.