Volvo’s Really Cool Idea That Could Solve Some Major Electric-Vehicle-Battery Issues [VIDEO]

(But it doesn’t sound cheap.)

Electric and hybrid vehicles are lauded as clean cars, but perhaps a better way of putting it is that they’re cleaner cars. After all, unless you live near a volcano, electricity comes largely from coal and natural gas — your electric green machine may be zero-emission while you’re driving but charging an electric vehicle (EV) battery means spewing carbon gas and particulate matter somewhere else. Also, the batteries that are used to power electric vehicles are heavy and take up valuable space.

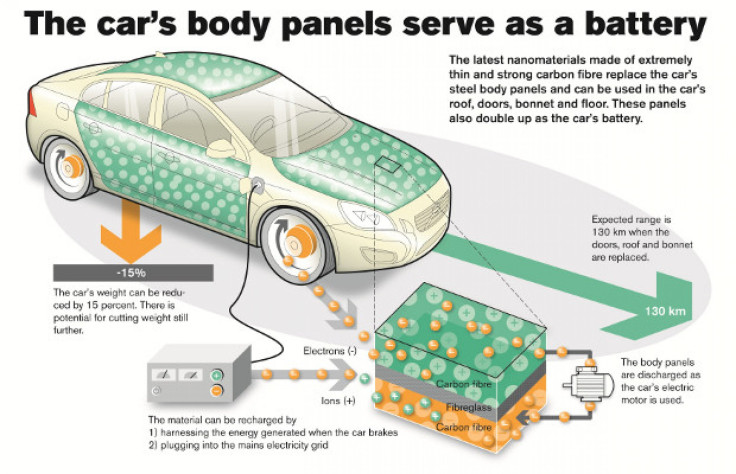

The engineers over at AB Volvo (STO:VOLV-A) have tackled this problem by making the car itself out of material that can store and discharge electrical power.

Here’s how it works: a thin layer of supercapacitors, which have long been considered the alternative to NiMH battery storage, is sandwiched between two layers of carbon fiber, the sturdy nanomaterial that’s starting to show up on some high-end cars because of its light weight.

This layered “fabric” can then be molded into the shape of a car’s body panels, such as the rear boot lid. Volvo claims that a vehicle’s entire steel frame could be made out of the stuff, greatly reducing weight without losing structural integrity while also acting as the electrical storage. Meanwhile anywhere an electric or plug-in hybrid vehicle stores its battery would be freed up for extra interior space and make the vehicle up to 15 percent lighter.

This isn’t the first time an automaker has explored the use of supercapacitors for electric storage and discharge; after all they charge and discharge faster than batteries. Toyota Motor (NYSE:TM) unveiled its Yaris Hybrid R concept at the Frankfurt auto show in September, but Volvo appears to be the first car company to explore supercapacitors as part of the material used for the body of the car.

This is high concept at best, however. Carbon fiber is expensive and making entire panels out of two layers is prohibitively expensive. But if the price can be brought down to even a high-end luxury level, the same people dropping six figures on Tesla’s Model S would flock to an electric car with a fraction of the charging time and bragging rights to the early adoption of a major innovation.

Now if we can only make electric cars that are truly carbon neutral. That would be a thing.

© Copyright IBTimes 2024. All rights reserved.