Lab-Grown Body Parts May Soon Be ‘Mass Produced’ And Even Affordable, Says UK Scientist

Would you like a custom nose with that order? Manufacturing tailor-made organs might sound like science fiction, but scientists say advances in medical research have made growing human organs of all kinds possible.

In fact, scientists in Britain are doing just that. According to the Associated Press, a hospital in north London is turning out ears, noses, blood vessels and even tear ducts, and implanting them in their patients, albeit only in a handful of subjects thus far. Still, researchers are optimistic about the prospect of harvesting human body parts on a larger scale.

"If people are not that fussy, we could manufacture different sizes of noses so the surgeon could choose a size and tailor it for patients before implanting it," Alexander Seifalian, a scientist at University College London who is leading the pursuit of lab-grown organs in the UK, told the Associated Press. "People think your nose is very individual and personal, but this is something that we could mass produce like in a factory one day."

Seifalian, whose team has molded a nose from a batter of stem cells and a salt and sugar solution for a man who lost his to cancer, said engineering body parts is “like making a cake.” When implanted – pending regulatory approval – the lab-grown nose would be the world’s first sniffer made partly from stem cells.

He also said that one day, factory-made organs could be on the market for a few hundred dollars.

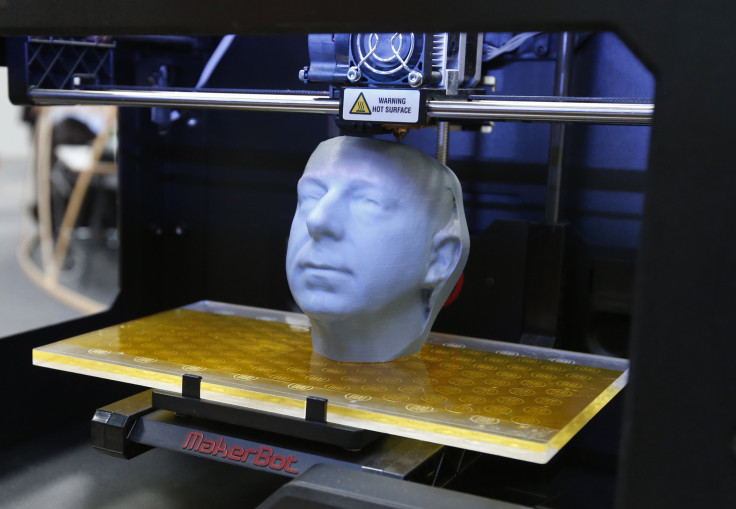

Using the human body to harvest complex tissues from which new organs can be grown is a burgeoning field of medical science. Already, several patients all over the world have received lab-grown body parts, and they’re working well. There have even been successful attempts at 3D-printing bioengineered organs, as was the case at the Wake Forest Institute for Regenerative Medicine in the U.S.

“We’ve already decellularized not just pig tissue, but discarded human organs, and we’re working with 3-D bio-printing of hearts, valves, tracheas and lungs,” Zain Khalpey, a leader in the world of bioengineering, told the Arizona Daily Star of Tucson in October 2013. “A lot of pieces are still missing. We are focusing on the metabolism of stem cells and their microenvironment so that they don’t die in the bioreactor.”

Of course, there are still challenges that need to be met. Creating complex structures that become a living, functioning part of the human body is a delicate process. Work like this remains experimental and costly, but that doesn’t keep leaders in the field from looking ahead.

"I'm convinced engineered organs are going to be on the market soon," said Suchitra Sumitran-Holgersson, a professor of transplantation biology at the University of Gothenburg in Sweden, told the Associated Press.

© Copyright IBTimes 2024. All rights reserved.