3D Printed Flexible Structures That ‘Remember’ Their Shapes Created By Scientists

3D printing is a nascent industry with many possible applications and scientists have now come up with a process in which the printed polymer, when exposed to a specific temperature, changes shape to go back to its original form “even after being stretched, twisted and bent at extreme angles.” Scientists from various universities collaborated to design a 3D printing method that uses light to print structures with very fine details.

The research is useful because shape-memory polymers “can be useful for a number of applications, from soft actuators that turn solar panels toward the sun, to tiny drug capsules that open upon early signs of infection,” according to Nicholas X. Fang, associate professor of mechanical engineering at Massachusetts Institute of Technology (MIT) and one of the co-authors of a new paper on the subject.

“We ultimately want to use body temperature as a trigger. If we can design these polymers properly, we may be able to form a drug delivery device that will only release medicine at the sign of a fever,” Fang said in a statement.

Other co-authors of the research paper included scientists from MIT, Singapore University of Technology and Design (SUTD), Rutgers University and Georgia Institute of Technology.

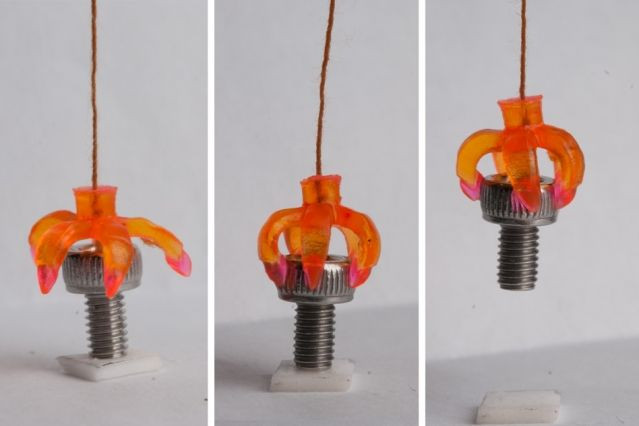

Qi Ge from SUTD said the process they have designed can be thought of as 4D printing, since the structures it prints “are designed to change over the fourth dimension — time.”

“Our method not only enables 4D printing at the micron-scale, but also suggests recipes to print shape-memory polymers that can be stretched 10 times larger than those printed by commercial 3D printers. This will advance 4D printing into a wide variety of practical applications, including biomedical devices, deployable aerospace structures, and shape-changing photovoltaic solar cells,” Ge said.

Printing using light is important because it allows for much finer detail compared with conventional 3D printing, allowing for printing of smaller structures. That, in turn, allows shape-memory polymers to recover their original shape faster.

“The reality is that, if you’re able to make it to much smaller dimensions, these materials can actually respond very quickly, within seconds. For example, a flower can release pollen in milliseconds. It can only do that because its actuation mechanisms are at the micron scale,” Fang explained.

To use light for printing, in a method they call microstereolithography, researchers fed the layer-by-layer model of the structure into a projector, each individual layer a separate image file. The projector then shines light on to a liquid polymer solution, one image at a time. The pattern in the image etches into the resin, which then solidifies.

The research paper was published in the journal Scientific Reports.

© Copyright IBTimes 2025. All rights reserved.