3D Printers Can Now Produce Magnets Of Any Shape With Customized Magnetic Fields

3D printing can solve a predicament when it comes to building strong magnets: how to build permanent magnets with specific magnetic fields. The technology, created by researchers at TU Wien and published in Applied Physics Letters, allows for the efficient production of complex magnets with customized magnetic fields.

"The strength of a magnetic field is not the only factor," says Dieter Süss, Head of the Christian-Doppler Advanced Magnetic Sensing and Materials laboratory at TU Wien, in a statement. "We often require special magnetic fields, with field lines arranged in a very specific way—such as a magnetic field that is relatively constant in one direction, but which varies in strength in another direction."

The key to build a magnet is building it with “sophisticated” geometric form.

"A magnet can be designed on a computer, adjusting its shape until all requirements for its magnetic field are met," said Christian Huber, a doctoral student in Dieter Süss' team.

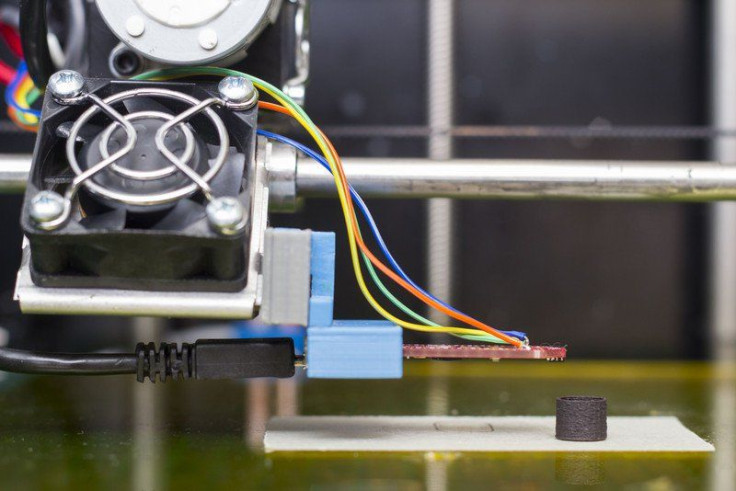

Once the shape is settled, a 3D printer is used to create magnetic materials similar to how printers produce plastic structures. Unlike most 3D printers, a magnetic 3D printer uses special filaments made of magnetic micro granulate that is bound together with polymer binding ingredients. The printer applies to heat to the material to create a 3D structure that is 90 percent magnetic material and 10 percent plastic.

Since the printed product is unmagnetized, the final step is expose the object to a strong external magnetic field to create a permanent magnet.

"This method allows us to process various magnetic materials, such as the exceptionally strong neodymium iron boron magnets," said Dieter Süss. "Magnet designs created using a computer can now be quickly and precisely implemented—at a size ranging from just a few centimetres through to decimetres, with an accuracy of well under a single millimetre."

The advantages of this technology are two-fold: it is fast and cost-effective.

"Now we will test the limits of how far we can go—but for now it is certain that 3D printing brings something to magnet design which we could previously only dream of," said Dieter Süss.

© Copyright IBTimes 2024. All rights reserved.