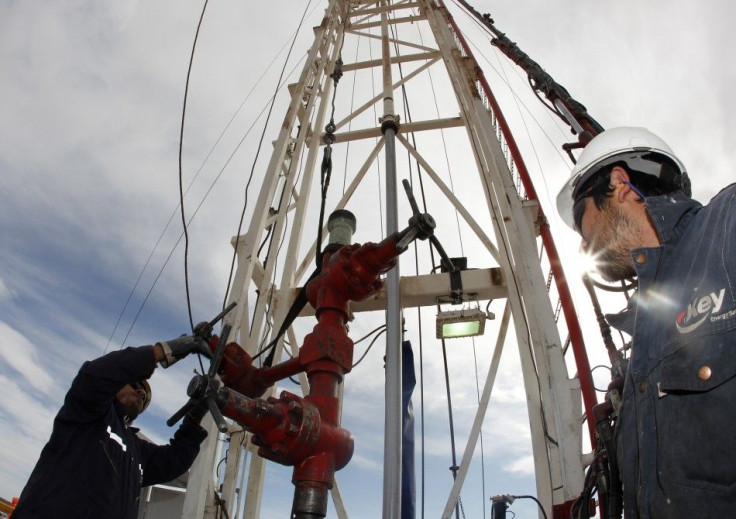

Hydraulic Fracturing: How Does a Natural Gas Well Get Drilled?

Just what is hydraulic fracturing, the controversial natural gas drilling technique that has sparked a rush for natural gas in the U.S.? There are strong opinions on both sides.

Industry players, such as the American Petroleum Institute and energy companies including Chesapeake and Cabot Oil & Gas, claim hydraulic fracturing holds the key to the nation's energy security by tapping into large reserves of fuel trapped underground. By drilling deep into the rock and then horizontally, one well can mine quantities of natural gas that multiple horizontal wells could not have.

The drilling innovation, though, has led to fears that large swaths of land and water tables are subject to pollution risks. Grassroots opponents and The Natural Resource Defense Council say hydraulic fracturing causes pollution and the EPA has linked groundwater contamination to hydraulic fracturing draft study from Wyoming. EPA regulators are visiting and retesting water samples in Dimock, Pa, after water tests there prompted the EPA into action.

EPA Administrator Lisa Jackson has testified before the U.S. Senate there are as of yet no proven cases that hydraulic fracturing causes groundwater contamination.

So what does a horizontal hydraulic fracturing natural gas well look like? Variations abound depending on geography, but each well more or less matches this anatomy. The following well design reflects a Barnett Shale gas well in North Texas.

Lets assume natural gas sits 8,000 feet below the surface, and an aquifer lies 1,000 feet below the surface. This is what the frackers actually do:

0- 1,050 ft.

Using a 12.5-inch drill, crews dig into the ground to roughly 50 feet (can be more) below the water table. Regulations in other states require different depths but in general, wells are drilled below any sources of ground water. Once completed, a 9.62-inch metal tube or casing is installed through the entire length of this hole. Crews then fill the annular, or circular, space between the surface casing and the raw earth with cement to seal off the aquifer from the eventual flow of natural gas back up the well.

1,050 - 7,500 ft.

Through the surface casing, a smaller drilling pipe is then inserted, and starting from the bottom of the casing pipe, crews dig a smaller hole 8.75 inches in diameter to 7,500 ft. This depth will be considered the kickoff point where drillers start the horizontal curve in any which direction depending on geologic surveys. The idea is to drill in the direction believed to yield the most hydrocarbons.

7,500 - 8,000 ft.

Using a specialized piece of equipment that can both drill down and at an angle, drilling crews will start extending the vertical well horizontally from the kickoff point. This portion can extend for another 1,000 ft., before the well levels off completely.

8,000 ft.

Once in the pocket of hydrocarbons, crews will continue drilling for another 2,500 or 3,000 ft horizontally. To the north in the Bakken Shale oil play of North Dakota and Montana, crews can drill horizontally for up to 10,000 ft. The size of the well depends on the company's lease. Once the well is drilled to the desired total depth, drilling equipment is taken out of the well and a second type of casing is run down the entire length of the well - usually measuring about 5.5 inches in diameter.

This production casing will stretch from the surface to total depth. Once in place, crews will cement the annular space between the production casing and the 8.75-inch hole the casing was introduced in.

Working from the bottom up, cement will be poured thoughout the horizontal and curved portion of the well and roughly 1,000 ft into the vertical shaft. The cementing helps push the drilling mud and other fluids up through the remaining 3.25-inch annular space separating the casing with the raw earth.

By now, the well is structurally complete. Once the cement has settled, a pneumatic perforator is sent down into the horizontal portion of the well, or total depth, and will punch holes through the casing. This is done so as to allow the fracturing fluids and sands to infiltrate the rock, fracture it, and collect any hydrocarbons located there.

One well can be hydraulically fractured many times. Crews can frack the same well progressing along its total depth by 50 feet at a time, or as desired, pumping hundreds of thousands of gallons of water and chemicals into the ground.

Important to note: one drilling rig can drill multiple wells.

© Copyright IBTimes 2025. All rights reserved.