3D Printing In Space: NASA Aims To Fabricate Tools, Spaceships, Habitats

NASA really likes the idea of using 3D printing in space -- and not just as a way to build a better pizza for astronauts.

3D printing, more formally known as “additive manufacturing,” is fast gaining prominence here on earth, but its applications are just as limitless in space. Instead of building a big bulky spaceship or habitat on Earth, why not just launch a little craft with an onboard 3D printer? Once a craft lands on the moon, a planet or perhaps a captured asteroid, the printer could use the materials around it to construct building blocks for structures, tools to repair ships and perhaps even other 3D printers (though this does raise the specter of the “gray goo” concept, where out-of-control self-assembling machines consume all available matter within reach).

Made In Space, a company that grew out of the NASA-partnered nonprofit Singularity University, is the brainchild of both space experts and 3D printing experts. The company has already conducted three test flights with its machinery, proving that it’s possible to have a working 3D printer in microgravity. It’s gearing up to send a 3D printer to the International Space Station in 2014 to investigate how well the printer will perform in space.

“The ability to 3-D print parts and tools on demand greatly increases the reliability and safety of space missions while also dropping the cost by orders of magnitude,” Made in Space CEO Aaron Kemmer told CNET. “The first printers will start by building test items, such as computer component boards, and will then build a broad range of parts, such as tools and science equipment."

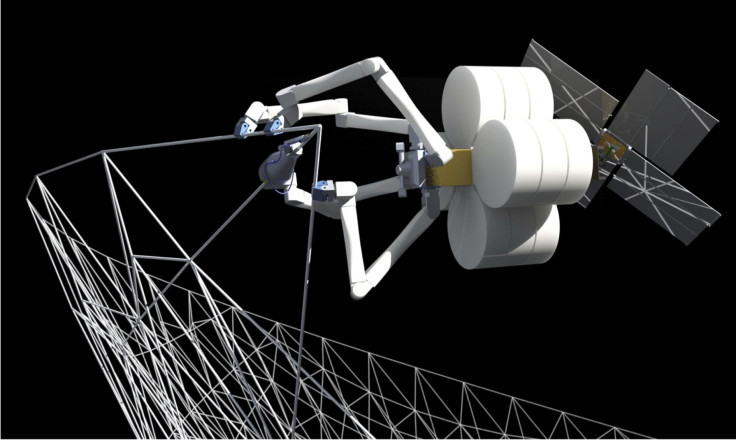

Washington-based Tethers Unlimited is developing its own 3D printing technique specifically designed for space called “Spiderfab.” With this method, the ingredients for a very large structure are launched in a compressed form. Once in orbit, machines can spin truss-like structures that can be combined to create large, lightweight devices. In May, Tethers Unlimited signed four contracts with NASA to develop SpiderFab and other technologies.

If SpiderFab proves workable, NASA could be making large antennas, solar arrays and other devices in orbit for a fraction of the current cost, according to the company. SpiderFab-made devices could also trap pesky orbital debris that poses a risk to both spacecraft and satellites.

“We’d like someday to be able to have a spacecraft create itself entirely from scratch, but realistically that’s quite a ways out,” Tethers Unlimited CEO Robert Hoyt told Space Industry News. "That’s still science fiction.”

The European Space Agency is already investigating the feasibility of using 3D printing and lunar soil to create moon habitats. Architects Foster + Partners, working with the ESA, have designed a dome-like structure that helps shield the habitat against meteor impacts and radiation. The U.K.-based company Monolite supplied the 6-meter-wide 3D printer, which sprays a binding solution onto a mixture of lunar soil and magnesium oxide, converting the material into a stony solid.

“Our current printer builds at a rate of around 2 [meters] per hour, while our next-gen design should attain 3.5 [meters] per hour, completing an entire building in a week,” Monolite founder Enrico Dini told the news site TG Daily.

© Copyright IBTimes 2025. All rights reserved.