MIT Scientists Develop Portable Device To Produce Biopharmaceuticals On Demand

In an attempt to aid doctors in remote areas, researchers from the Massachusetts Institute of Technology have designed a portable system to manufacture a number of biopharmaceuticals on demand.

In a paper published Friday in the journal Nature Communications, the team demonstrated that the system could be used to produce a single dose of treatment from a device containing a small droplet of cells in a liquid.

“Currently, manufacturing of biologic drugs in the biopharmaceutical industry relies heavily on large-scale fermentation batches that are frequently monitored offline, to ensure a robust process and consistent quality of product,” the study explains.

However, this system could possibly be carried to areas that do not have access to this level of production and even be used to manufacture vaccines to prevent a disease outbreak in a remote village, a press release stated senior author Timothy K. Lu, head of the Synthetic Biology Group at MIT’s Research Laboratory of Electronics, as saying.

“Imagine you were on Mars or in a remote desert, without access to a full formulary, you could program the yeast to produce drugs on demand locally,” Lu said.

Despite being expensive, the new system is based on a programmable strain of yeast, Pichia pastoris, which has multiple uses and can grow to very high densities on simple carbon sources.

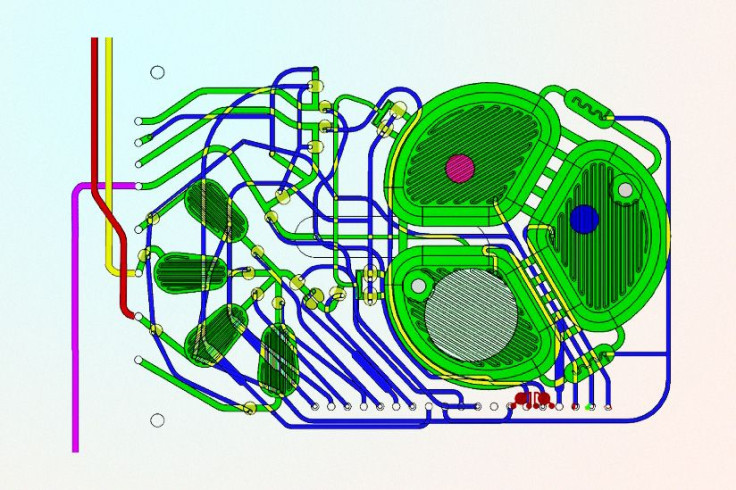

The yeast was exposed to estrogen β-Estradiol and held within a millimeter-scale table-top microbioreactor that contained a microfluidic chip.

“If you could engineer a single strain, or maybe even a consortia of strains that grow together, to manufacture combinations of biologics or antibodies, that could be a very powerful way of producing these drugs at a reasonable cost,” Lu explained.

In addition to that, the paper states that using the machine to produce vaccines would be valuable as it could reduce any “undesirable background production.” Portability is another key positives of the new system.

According to Luke P. Lee, a professor of bioengineering at the University of California, Berkeley, the researchers have demonstrated a very logical and practical way to produce biologic drugs.

“It is a pragmatic solution for biomanufacturing, and the team’s flexible and portable platform shows an authentic way of producing personalized therapeutics,” Lee, who was not involved in the study, said in the statement.

© Copyright IBTimes 2025. All rights reserved.