Self-Folding Origami Structures Use Light That Changes Shape Of Polymer

Origami is an old Japanese art of folding paper into various decorative shapes, and requires a certain amount of nimbleness of the fingers. But a new method developed by researchers uses layers of a thin polymer that fold themselves into origami structures under the effect of light.

The self-folding origami technique was developed by researchers from Georgia Institute of Technology and Peking University in China, who published a paper on the subject Friday in the journal Science Advances. And the possible applications of the technique aren’t just decorative — it can find uses in a range of fields, including “soft robots, microelectronics, soft actuators, mechanical metamaterials and biomedical devices,” according to the researchers.

The paper, titled “Origami by frontal photopolymerization,” explains the method. A thin layer of liquid acrylate polymer is placed in a plate or between two glass slides, and then light from an LED projector is shone onto the polymer. A photo-initiating material mixed into the polymer causes it to harden under the effect of light, while a light-absorbing dye in it controls the amount of light absorbed. The areas that receive less light end up bending more, and the bending process starts when the polymer film is removed from the liquid.

Jerry Qi, a professor in the Woodruff School of Mechanical Engineering at Georgia Tech and a co-author of the paper, said in a statement Friday: “During a specific type of photopolymerization, frontal photopolymerization, the liquid resin is cured continuously from the side under light irradiation toward the inner side. This creates a non-uniform stress field that drives the film to bend along the direction of light path.”

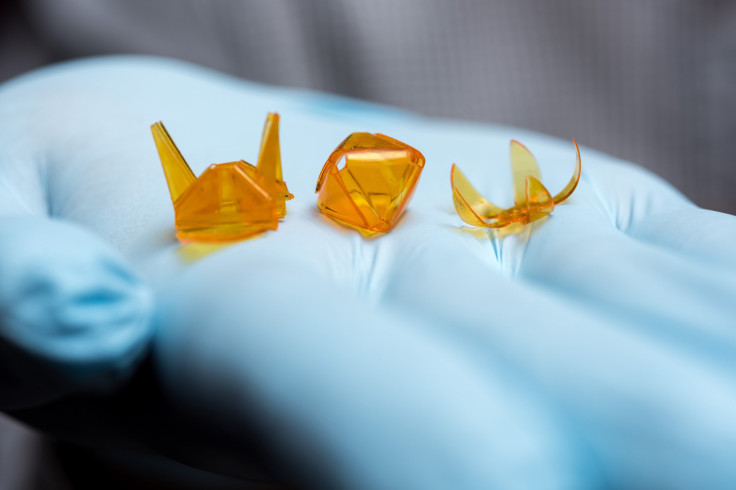

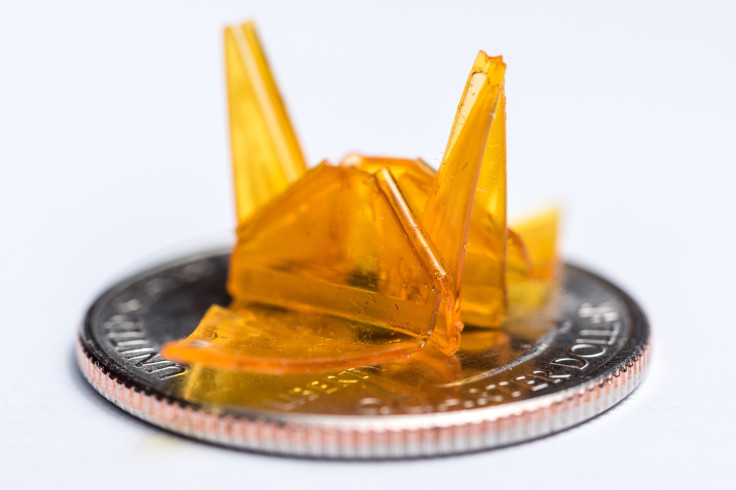

To amplify the bending of the polymer and make more complex origami structures, the researchers shone light on both sides of the polymer. And they created several structures like flowers, birds, tables, capsules and the well-known tassels of the Miura fold.

Read: 3D Sound Shapes Make Acoustic Holograms

“We have developed two types of fabrication processes. In the first one, you can just shine the light pattern towards a layer of liquid resin, and then you will get the origami structure. In the second one, you may need to flip the layer and shine a second pattern. This second process gives you much wider design freedom,” Zeang Zhao, a doctoral student at Georgia Tech and Peking University, said in the statement.

After about five to ten seconds of light being shone onto the polymer, a film about 200 microns thick is formed. The structures produced by the researchers used multiple layers of the polymer and were all about half inch in size. According to Qi, the size limit for structures created using this method is about one inch.

The method would theoretically work with a large number of photo-curable polymers, and the system could be connected to a computer to generate precise three-dimensional models for generating grayscale patterns in which light would shine on the polymer.

“We have developed a simple approach to fold a thin sheet of polymer into complicated three-dimensional origami structures. Our approach is not limited by specific materials, and the patterning is so simple that anybody with PowerPoint and a projector could do it,” Qi said.

© Copyright IBTimes 2024. All rights reserved.