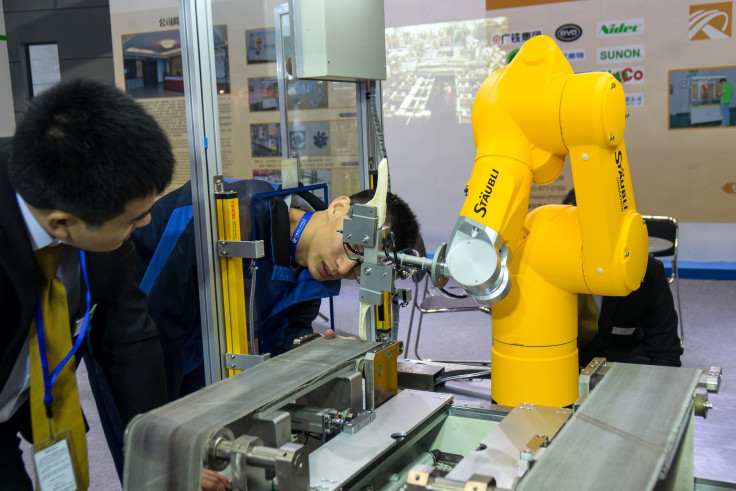

China’s Robotics Revolution: Apple Supplier Foxconn Replaces 60,000 Workers At One Factory Alone, Report Says

China’s labor-intensive industries have been rapidly shifting toward jobs-killing automation in recent years, with a world-leading 16 percent rise in industrial-robot sales last year alone. Now, a new official estimate has put a spotlight on some of the effects of these investments in China’s electronics-manufacturing center.

Taiwan’s Hon Hai Precision Industry Co., more commonly known as Foxconn, has shed 60,000 workers at one factory alone, according to a recent report in the South China Morning Post. Foxconn is most famously known as Apple’s largest contract manufacturer, which has faced criticism over the treatment of its workers and for a string of worker suicides.

“The Foxconn factory has reduced its employee strength from 110,000 to 50,000, thanks to the introduction of robots,” Xu Yulian, spokesman for Kunshan city, told the Post. “It has tasted success in reduction of labor costs ... More companies are likely to follow suit.”

Increased industrial automation is part of a growing global trend that promises to raise increasing challenges on how to deal with the idle labor (known in economics parlance as “slack”) created by replacing low- or modestly skilled workers with robots.

In 2014, athletic wear giant Nike Inc. said it shed 106,000 jobs in the previous year by shifting Asian contract production to more modern factories that use automation to reduce dependence on workers.

Kunshan, located near Shanghai in Jiangsu province, is home to hundreds of factories that help satisfy the world’s appetite for electronics. More than two years after an industrial explosion killed 146 at a plant supplying components to General Motors, blamed on poor safety standards, many companies in the area are investing heavily in reducing the number of workers at their plants.

About 600 local plants are in the process of investing in automation in a bid to boost growth while lowering the cost of labor. Last year alone, 35 Taiwanese companies operating plants in Kunshan, including Foxconn, invested 4 billion yuan ($610.1 million) for industrial robots.

In the U.S., the debate over automation has touched numerous industries, such as logistics and automotive. More recently, opponents of minimum wage hikes have warned that fast-food workers could easily be replaced by robots.

On Tuesday, former McDonald’s USA CEO, Ed Rensi, said it costs less to buy a $35,000 robotic arm to bag French fries than it is to pay a worker $15 an hour. If robots are poised to take over jobs that often don’t pay wages that cover living expenses in the U.S. or elsewhere, then the question remains about what to do with workers who don’t earn enough — employed or otherwise — to pay basic living expenses.

© Copyright IBTimes 2025. All rights reserved.