Cool Clothes: New Textile Could Reduce Need For Air Conditioning In Summer

“If you can cool the person rather than the building where they work or live, that will save energy.” This isn’t an environmentalist’s pipe dream, it’s what Stanford University professor Yi Cui said about a new textile his group of researchers has just developed. According to researchers, the plastic-based fabric does a better job of cooling people than natural or other synthetic textiles.

Blending nanotechnology, photonics and chemistry to allow the body to discharge heat more rapidly than traditional textiles, the new fabric would make the wearer about 4 degrees Fahrenheit cooler, according to a statement on the Stanford website. It can do so by allowing not just evaporation of sweat (the most common way the body cools down in hot conditions), but also by allowing the bodies' infrared radiation to pass through.

Shanhui Fan, another Stanford professor and co-author of a paper on the fabric, explained: “Forty to 60 percent of our body heat is dissipated as infrared radiation when we are sitting in an office. But until now there has been little or no research on designing the thermal radiation characteristics of textiles.”

The researchers started with polyethylene — commonly used in kitchens as the clear, clingy plastic to wrap food — which already allows infrared radiation to pass through. But since the kitchen wrap is both waterproof and see-through, it is not the most practical fabric for clothing.

They found a variant of polyethylene, which is opaque but still allows infrared radiation to pass through. They treated it so it allowed water vapors to pass through as well, allowing the plastic to breathe like a natural fiber, the statement said.

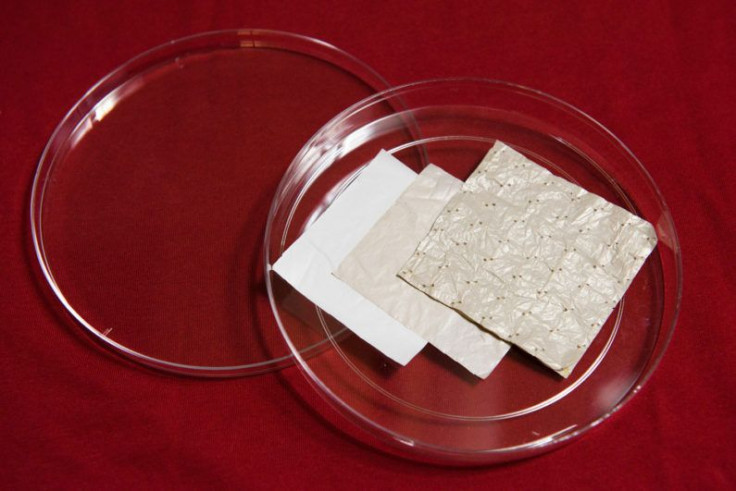

Testing a three-ply construct of their plastic textile, they compared it with cotton fabric of similar thickness to see how much heat was dissipated from a surface under each material. They found that cotton kept the surface 3.6 degrees Fahrenheit warmer than the plastic textile.

The researchers are now working on furthering their work, such as adding more colors, textures and cloth-like characteristics to the material.

“If you want to make a textile, you have to be able to make huge volumes inexpensively,” Cui said in the statement. And since the polyethylene used is already mass produced for the battery industry, we could see bolts of this stuff rolling out soon.

The research, titled “Radiative human body cooling by nanoporous polyethylene textile,” was published Friday in the journal Science.

© Copyright IBTimes 2025. All rights reserved.