Peacock Spider Inspires Tiny Origami Soft Robot At Harvard [Video]

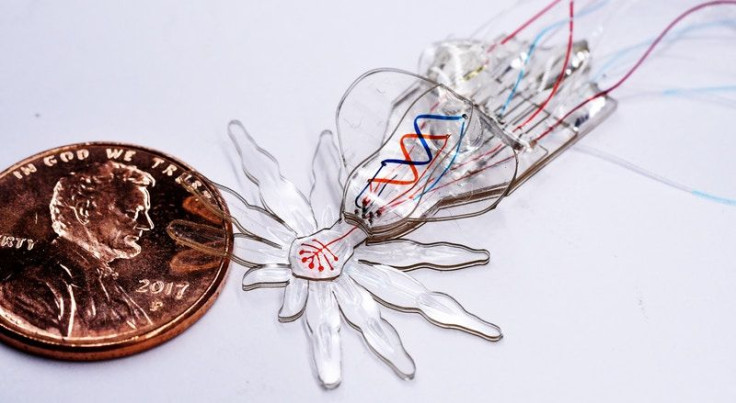

In a bid to aid human efforts in medicine and related fields, a team of engineers at Harvard has developed a tiny soft-robot, one that looks similar to the colorful peacock spider and performs a range of motions on the millimeter scale.

The spider bot, nicknamed MORPH, was created with a novel fabrication technique developed to add flexibility into rigid machines operating today. The method is still at a nascent stage, but the team believes future work around these lines could make machines capable enough to enter the human body for microsurgery or other places that are difficult to reach.

“By developing a new hybrid technology that merges three different fabrication techniques, we created a soft robotic spider made only of silicone rubber with 18 degrees of freedom, encompassing changes in structure, motion, and color, and with tiny features in the micrometer range,” Sheila Russo, one of the researchers behind the tiny robot, said in a statement.

These capabilities, as Russo described, mark a major upgrade over conventional small soft-robots that carry a mere one degree of freedom and trigger only a single change in shape or motion at a time. The team even released a video to showcase the functioning and capabilities of the spider-inspired soft-robot.

In order to create this millimeter-sized machine, Russo and colleagues used soft lithography and laser-micromachining to produce 12 layers of elastic silicone. The layers were combined to form a peacock spider-like structure and connected to thin, hollow tubes.

These tubes serve as a gateway for special micro fluids, which trigger the entire functioning of the tiny spider bot, starting from the slow movement of its limbs to its color-changing abilities.

In the clip, the researchers used curable resin in some microfluidic channels to operate the spider bot. They even puffed up its abdomen and bent its legs downwards to demonstrate how it could hold on to a deformed position by the application of UV light, which hardens the fluid. The remaining fluid channels, as the researchers added, are either used to add color to the eyes or abdomen of the spider or to simulate walking-like patterns.

The study titled, "Increasing the Dimensionality of Soft Microstructures through Injection‐Induced Self‐Folding," was published Aug. 6 in the journal Advanced Materials.

© Copyright IBTimes 2025. All rights reserved.