MIT Scientists Perfect 3D-Printing System That Uses Glass As Building Material

The art of 3D printing already utilizes a variety of materials including ABS plastic, polyamide or nylon, PLA, wax, polycarbonates and photopolymers. And now glass could soon be one of the general materials used in this process of additive manufacturing.

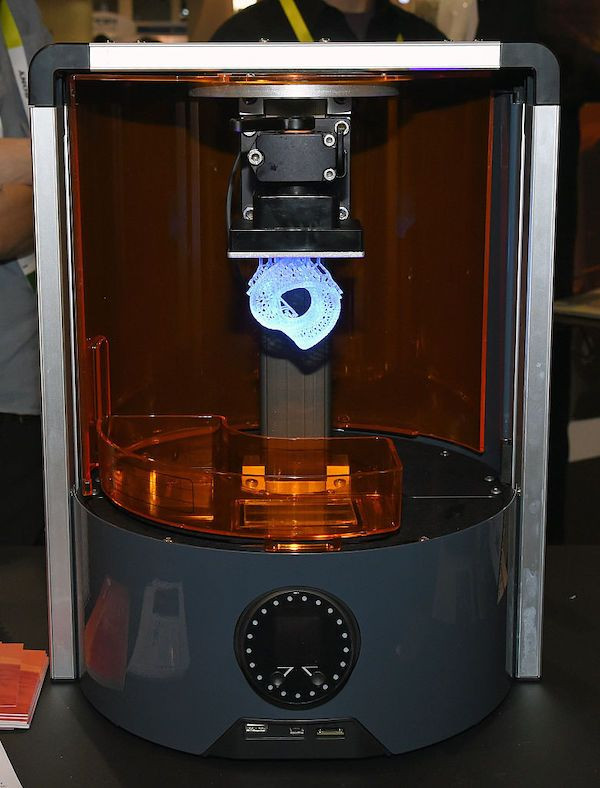

Scientists at Massachusetts Institute of Technology (MIT) have recently perfected the process of 3D printing using molten glass. The system that they came up with manages to have full control over the hot material, resulting to stable final products that were previously difficult to make with 3D printing.

The team described the system, called G3DP2, in their study published in 3D Printing and Additive Manufacturing, saying that it’s “a new AM platform for molten glass that combines digitally integrated three-zone thermal control system with four-axis motion control system, introducing industrial-scale production capabilities with enhanced production rate and reliability while ensuring product accuracy and repeatability, all previously unattainable for glass.”

This is a breakthrough in 3D printing for glass is a material that has complex chemistry and requires extreme temperatures to be melted and moulded into structures. Despite being one of the oldest manufacturing materials, there are still persistent challenges that come with glass production and design. This explains why it took time before glass was used in 3D printing.

The system’s setup is composed of a closed, heated box that’s tasked to hold molten glass and a secondary box that’s thermally controlled. The latter is where glass is transformed into three-dimensional objects. The glass extrusion system is carefully controlled to ensure that impurities and structural problems won’t disrupt the crystallization process. The resulting clear glass structures can be used for building or for decoration, as per TechCrunch.

One of the finished products that the G3DP2 was able to make was a set of 3-meter-tall glass columns used for Milan Design Week 2017. The installation highlighted the geometric complexity, strength, accuracy and transparency of 3D-printed glass and showed off the potential of the invention in architectural design.

The MIT researchers who worked on the system — Chikara Inamura, Michael Stern, Neri Oxman, Daniel Lizardo and Peter Houk — hope that their invention could open doors for more glass applications in 3D printing, seeing that the material has numerous uses in various industries.

“In the future, combining the advantages of this AM technology with the multitude of unique material properties of glass such as transparency, strength, and chemical stability, we may start to see new archetypes of multifunctional building blocks,” the creators wrote in their study.

© Copyright IBTimes 2025. All rights reserved.