Graphene, Silver Combination Cracks Fragile Smartphone Touchscreen Problem With 'Potato Stamp' Technique

That mini heart attack when you drop your precious smartphone is all too real. Smartphones have become a steadfast addition to our everyday lives and most people spend hours a day glued to their screens. The frustrating thing about smartphones is the fragility of their screens. You can never predict the fall that will spread that spider-web of dread across your phone screen.

A team of scientists from the University of Sussex, U.K., seem to be on the right track to cracking this major dilemma.

According to a press release Wednesday on the University of Sussex website, they developed a new technique that could make your smartphone screen cheaper to produce, faster, more efficient, flexible and eco-friendly. All this happened when they decided to replace one material — indium tin oxide (ITO) — with a combination of graphene and silver nanowires, to create a film which matches the performance of regular screens, but at a fraction of the cost.

ITO is one of the main components used in phone touchscreen manufacturing. They are used as the conductive film on top of your smartphone screen. When current is passed through ITO it forms an electric field on the screen which when touched, causes changes in this field. When your finger or a suitable object touches the screen, it changes the electrical state at the point of contact. The device then tracks the changes and reacts by completing the tasks according to the movement of your finger.

ITO is used widely in touchscreen technology because it is transparent and can be made into an electrically conductive film on top of the screen. However, it has got some major downfalls.

It is a really expensive material. According to a Science Alert article released in 2015, ITO now contributes up to 40 percent of the cost of a smartphone or tablet, and while the cost of memory chips and processors continue to drop, the materials being used to build our screens and displays is holding us back from developing bigger and better technologies. Other materials that serve the purpose, such as silver, are also expensive.

The process of mining and producing ITO is also very harmful to the workers and the environment. Furthermore, it’s very brittle. This property makes smartphone screens very fragile.

Matthew Large, lead researcher on the project at the School of Mathematical and Physical Sciences at the University of Sussex, said in a report by the Telegraph that "The reason that the screen on your phone is so easy to break is that the touch sensor is based on indium tin oxide. This material is very brittle, so needs to be deposited on a strong, hard surface like glass."

"It’s the glass layer that cracks if you drop your phone on a hard surface, or sit down on it by accident," he added.

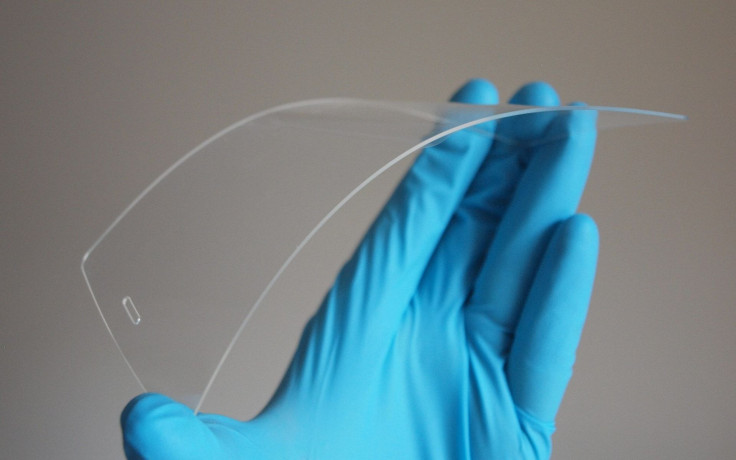

The latest technology developed by the team negates the need for a hard glass surface. This is because of the silver nanowire-graphene hybrid films the team has developed, which are very flexible.

Graphene is a two-dimensional, atom-thick carbon material. They used the famous "potato stamp" technique to get the graphene and silver nanowire films to combine to form a thin conducting layer. The researchers say this will solve the issue of cracked screens.

"While silver nanowires have been used in touch screens before, no one has tried to combine them with graphene. What's exciting about what we're doing is the way we put the graphene layer down,” Professor Alan Dalton, from the School of Mathematical and Physical Sciences, said in the University of Sussex report. "We float the graphene particles on the surface of water, then pick them up with a rubber stamp, a bit like a potato stamp, and lay it on top of the silver nanowire film in whatever pattern we like."

"And this breakthrough technique is inherently scalable. It would be relatively simple to combine silver nanowires and graphene in this way on a large scale using spraying machines and patterned rollers. This means that brittle mobile phone screens might soon be a thing of the past," he added.

The paper, "Selective mechanical transfer deposition of Langmuir graphene films for high-performance silver nanowire hybrid electrodes" was published in the American Chemical Society journal Langmuir on Sept. 29.

© Copyright IBTimes 2024. All rights reserved.