Power Without Compromise: The Emil Motors Vision for EVs' Magnet-Free Future

Emil Motors was founded by engineers Maximilian Güttinger and Johannes Unhold with the objective of redesigning the electric motor to eliminate reliance on rare earth materials while maintaining performance. The founders initially connected through a shared interest in sailplanes and engineering, which led to a collaborative effort focused on sustainable technology for electric mobility.

At the time of the company's inception, both Güttinger and Unhold were pursuing mechanical engineering at separate universities. They later chose to discontinue their academic paths to focus entirely on developing an electric motor that could address industry challenges related to material sourcing and performance limitations.

Their early development work covered various components of electric vehicle (EV) systems, including batteries and drivetrains. "We realized it was the motor that has perhaps the most untapped potential. But it's also the one that poses an urgent problem," Güttinger shares. The EV industry's reliance on permanent magnets, especially those containing rare earth minerals, struck them as a vulnerability.

"These materials are almost entirely mined and processed in one country. That makes them expensive, ethically questionable, and strategically risky," states Güttinger. "We thought, 'What if we could build a motor that didn't need any rare earth materials but delivered the same power, efficiency, and scalability?" That question became the pair's mission.

In 2021, Güttinger and Unhold started working seriously on the problem. They aimed to prove that rare-earth-free motors could compete head-to-head with the best permanent magnet machines. A year later, the idea crystallized. The visionaries doubled down on their motor concept, laying the technical and strategic foundation that would lead to the formal founding of Emil Motors in 2023.

Now, the Germany-based company is known for its flagship innovation, a magnet-free axial flux induction motor that challenges two limitations in the industry. Induction motors have been viewed as less efficient and lacking in torque compared to their permanent magnet counterparts. Emil Motors turns that assumption on its head by combining axial flux geometry and induction motor principles.

"Axial flux motors generate higher torque because of their wider rotor radius, allowing magnetic forces to act with greater leverage," Unhold explains. "We adapted this geometry for induction and achieved torque and efficiency metrics that can rival conventional EV motors."

The real breakthrough is in how the motor generates motion. Instead of using magnets to pull the rotor into action, Emil Motors' induction system creates a magnetic field through alternating current. This magnetic field induces current in the rotor itself. "It's similar to how an induction stovetop heats a pan without direct contact," Güttinger says.

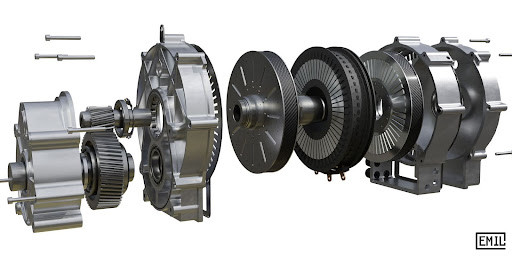

The motor's design utilizes a dual-rotor, single-stator layout. It's carefully optimized for manufacturing and reliability. The structure can cancel out axial forces that would otherwise strain the motor over time. Meanwhile, the segmented stator can allow for a highly efficient automated winding process.

Integrated oil cooling channels can deliver direct thermal management where it matters most, and the company's proprietary aluminum cage rotor can boost electrical performance without complex cooling or power electronics.

All of this adds up to a motor that delivers 330 kW of shaft power, 450 Nm of peak torque, and weighs just 35 kilograms, without a gram of rare earth material. Emil Motors' magnet-free machine relies only on copper, aluminum, steel, and plastic. These materials are globally available, recyclable, and free of geopolitical entanglements.

The company's ambition is to bring this technology to real-world vehicles. As of mid-2025, Emil Motors is actively engaged in discussions with several major manufacturers and is preparing for the release of full-scale test results in August.

With patents secured across multiple markets, including the United States, and a production-ready design already in hand, Emil Motors is poised to enter large-scale manufacturing and begin deployment in high-volume EV platforms. Its adaptable architecture means the motor could also find use in hybrid drivetrains and even applications beyond the automotive industry.

© Copyright IBTimes 2025. All rights reserved.