Secrets Of Tougher Synthetic Ceramics Learnt From Brittle Starfish

Humans have constantly designed and upgraded technology based on nature and the efficient evolutionary designs of many creatures. The dragonfly inspired the helicopter, Velcro was inspired by the barbs of a Thistle plant and building materials inspired by bird bones.

Now, a team of researchers has discovered how a brittle star can create material like tempered glass underwater.

The findings, published in the journal Science, show that these underwater creatures create a protective covering for sensitive lenses on their arms that could give us structural clues to designing tough ceramics that could improve optical technology like lenses, automotive turbochargers, and even biomaterial implants.

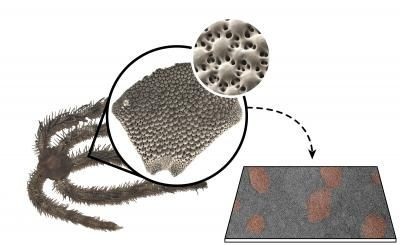

This brainless echinoderm (sea stars, sea urchins, and cucumbers) live in the coral reef environment on ocean floors. They have thousands of focal lenses located on the arms made of chalk. These are powerful and accurate eyes that have been evolved to avoid the blurring our spherical lenses produce underwater. The arms of this creature are covered in very sophisticated, identical cylindrical lenses that help focus the light from surroundings into the nerve bundle of the creature that helps it see and maneuver.

One surprising thing about these lenses is they are totally inorganic. The brittle stars arms have near-perfect microscopic lenses that are made of calcite. They are more sophisticated than anything humans can produce, say engineers in a 2001 news report on science journal Nature.

Keen to copy the trick, Boaz Pokroy, and his team, from the Technion-Israel Institute of Technology, for the past three years have been trying to study these lenses to implement them in mass-produced technology.

Thanks to research done on three ESRF beamlines (studies), ID22, ID13, and ID16B, among other laboratories, they have figured out the unique protective mechanism of highly resistant lenses.

"We have discovered a strategy for making the brittle material much more durable under natural conditions. It is 'crystal engineering' and tempering without heating and quenching - a process that could be very useful in materials engineering", explains Pokroy in the press release on the Technion website.

Tempered glass is just normal glass that has been compressed under extreme pressure and temperature and then rapidly cooled. It makes glass more compact than in its natural state. This happens because the outside of the material cools more quickly than the inside and thereby compresses the inside.

Ophiocoma wendtii (brittle star) lenses are created in the open sea, at room temperature, unlike tempered glass which required mechanical assistance.

"We understood that we had nanodomains after this experiment, so we did some transmission electron microscopy at home, then came to ID13 to map the nanodomains and finally to ID16 to do tomography on how the different particles arrange themselves in different layers", he adds.

The international team, which includes scientists from U.S., Italy, and Berlin discovered that the crucial stage in the process of lens formation is the transition from the amorphous phase - the phase between liquid and solid - to the crystalline phase.

They found that the calcite nanoparticles, which are rich in magnesium are very low density. This causes them to separate from the rest of the material rather easily.

The difference in concentration of magnesium in the calcite particles causes various degrees of hardness, density, and pressure in different regions of the material.

The Magnesium-rich particles cause a pressure on the inside of the lens. This causes crystallization and forms a clear and tough crystalline material.

"Nature exhibits tremendous creativity in improving the organism's abilities in various contexts such as strength, sensing, and self-defense. Here, too, in the process of creating hardy and precise transparent lenses, we see tremendous efficiency in the use of existing raw materials under conditions in the natural environment,” the team said the release.

© Copyright IBTimes 2025. All rights reserved.