Science Meets Sustainability: This Research Company's Unbelievable Discovery Dissolves Plastic In 15 Minutes

What started off as a task to find a solution for unsustainable food packaging has since evolved into a project that has the potential to save billions of pounds of plastic from infiltrating our environment each year. Meet the individuals behind this revolutionary finding.

All of the world's greatest innovations work to solve a problem, and Denovia Labs, by Nick Spina and Istok Nahtigal is one of them. Together they have discovered a way to remanufacture plastic that is 10x more economic and cost-efficient than methods used by current industry leaders.

Through their material up-cycling process, they are able to re-use the same plastic materials in a continuous cycle, which has never been done before. They valorize those materials, combining them into virgin quality plastic, reducing plastic waste tremendously.

Nahtigal is a physical organic chemist and researcher with the Fanshawe Centre for Research & Innovation, and he was approached by Spina, founder of an ethical meal delivery company called ethey, to find a solution for his company's plastic food packaging.

Currently, ethey operates a closed-loop system, where all of their leftover food scraps are delivered to an on-site worm farm, and turned into manure, which is then used to grow its produce. But the problem is, the package isn't sustainable. That's what prompted Spina to approach Nahtigal.

But when they met for the first time, little did they know that they would soon make a discovery that holds the power to change the world and restore hope in the hearts of millions of people worldwide.

"What we ventured into was looking for a solution for LiveFit's packaging, which is composed of fiber, plastic and things of that nature," Nahtigal tells us. "Majority of companies are using fiber based plastics which don't actually classify as being biodegradable," he adds.

The plastics that Nahtigal first started experimenting with were the more common ones that make up the majority of packaged goods, such as water bottles and containers. Soon, Nahtigal and his team discovered a chemical process that could break plastic back down into its original components, known as monomers, within a record breaking five to fifteen minutes.

"It was essentially a two part project because we were looking at the fiber component and the textiles. And honestly when we were doing the project the fiber actually presented challenges in getting its yields to break down. But the plastic was a surprise. It worked and then we just kept testing it, improving it and trying other methods, essentially trying to make it fail and it was actually very hard to make it fail," Nahtigal exclaims.

The result of his research is a process that can break down plastics into monomers that are chemically identical to what petroleum companies produce. So the corporations that are making the plastics can buy the material directly from Denovia Labs, and they don't actually have to change their process in any way. "It's literally a drop in replacement," he adds.

So why is this important?

Nahtigal and Spina's plastic upcycling process is both economic and scalable. Of course the current industry standard process successfully melts down plastic, but Spina tells us that after you repeat the process five or so times the plastic becomes very brittle and weak, and you actually can't recycle it anymore.

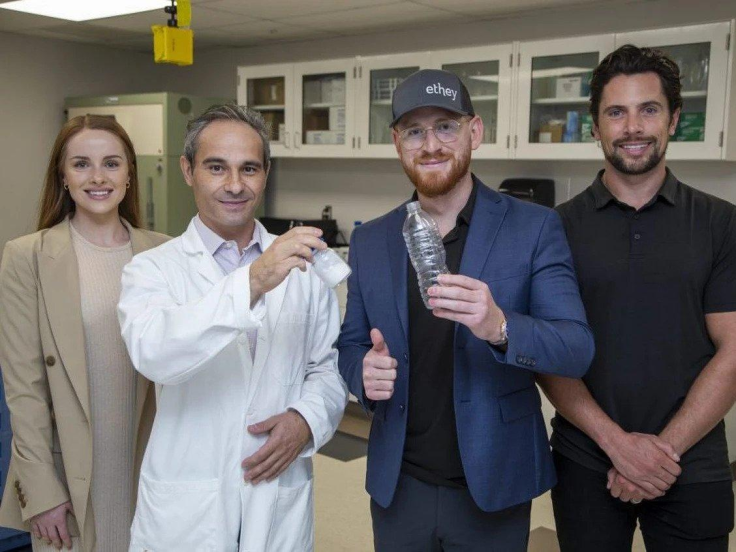

Left to right: Samantha Sowerby, Istok Nahtigal, Nick Spina, and Kyle Standaert

With their new discovery, Nahtigal and Spina are giving birth to a new beginning in sustainability, by providing longevity to the compound and making it almost infinitely reusable.

"That's where our process becomes very helpful because we can just continue to rebirth it back into its virgin state and it becomes a new plastic again," says Spina. "We're really at the start of something fantastic here."

This innovation wouldn't have been possible unless Nahtigal and Spina worked together to tackle our world's plastic problem. Their teamwork has led to a discovery that has the potential to change our entire world.

"Istok and I are very similar in a lot of ways, but on different ends. I take care of the business side and he takes care of the science side. Our conversations are very invigorating because I think we excite each other every time we get on the phone," Spina adds.

"I think our success is actually going to come from that, because no one person is an expert in everything and you have to be able to complement and work together with good people. And the team that we're putting together with Denovia Lab and ethey group, is poised for success," Nahitgal concludes.

If you are interested in learning more about Denovia Labs as Istok Nahtigal and Nick Spina continue to scale across North America, be sure to check out their website today.